About the Article

Methods of increasing the operating reliability of power transformers, autotransformers and shunting reactors in order to reduce the risk of damage, which accompany internal short circuits and equipment fires and explosions, are considered.

Source: magazine Élektricheskie Stantsii, No. 9, September 2014, pp. 41 – 48M. M. L’vova, S. Yu. L’vov, V. B. Komarov, E. O. Lyut’ko, V. P. Vdoviko, V. V. Demchenko, S. G. Belyaev, V. A. Savel’ev, M. Yu. L’vov, and Yu. N. L’vov

Introduction

Internal short circuits cause the most serious damage to power transformers, autotransformers and shunting reactors, operating at a voltage of 110 kV and higher (henceforth simply transformers). Analysis has shown that damage, which accompanies internal short circuits, represents 80% of the total amount of damage to windings, 89% of the total number of breakdowns of high-voltage leads, and 25% of the total number of breakdowns of regulators under load. In more than 30% of such cases the damage is caused by explosions and fires.

The purpose of this paper is to consider the problem of increasing the operating reliabilities of transformers by reducing the risk of damage, which is accompanied by internal short circuits, explosions and fires in transformers. The main factors which give rise to an increase in the number of transformer breakdowns are as follows:

- An increase in the number of transformers operating for longer than their minimum life of 25 years, laid down by the standard.

- The use of transformers beyond the limits of their normal parameters;

- The lack, in the standard documents, of a number of criteria which are necessary in order to obtain more complete and reliable information, which will enable the operating capability of transformers to be estimated

On the whole, there are a sufficient number of effective documents which enable the state of transformers to be determined and whether they are capable of further use.

Nevertheless, as experience shows, ionization and thermal processes can occur in transformers in local regions of the insulation, which lead to internal short circuits, explosions and fires in equipment, in a time less than the monitoring periodicity laid down in the Regulating Document (Standards for testing electrical equipment).

The central ideas when diagnosing the technical state of a system and estimating the risk are the “limit state” and the “limit state criteria”.

According to the State Standard GOST R 53480–2009, the “limit state is the state of a component, for which its further use is impermissible or undesirable for reasons of danger or for economic or ecological reasons”; “limit state criteria are indicators of a limit state for which a decision must be taken regarding the state of the equipment.” At the present time, the procedure and criteria for determining the limit state of power transformers are not given in the standard technical documents.

Nevertheless, experience acquired over many years of use provides a scientific basis for a procedure for estimating the limit state of power transformers operating at a voltage of 110 kV and higher. The main indicators and criteria of the limit state of transformers are as follows:

- Wear of the winding insulation.

- Dangerous deformation of the windings, due to high short circuit currents.

- Dangerous contamination of the windings by metal-containing colloidal particles, which are formed as a result of the interaction of the oil with constructional materials.

When the degree of polymerization of the paper insulation of the windings is reduced to 250 units, the following occur:

- There is a not less than fourfold reduction in the mechanical strength of the insulation compared with the initial value;

- Loss of water (dehydration) from the paper insulation at a level of 6% by mass and greater

Possible damage to the winding insulation for a reduction in the degree of polymerization to 250 units:

- Damage to the winding insulation from the axial pressure of forces when there are short-circuit currents;

- A reduction in the electric strength between the windings when the insulation on the conductor is damaged (rupture or a crack) by a factor of 1.5 – 2. The calculated safety factor of the electric strength in different transformer winding structures varies from 1.1 to 1.7;

- Heating up of part of the insulation due to dielectric losses, which is accompanied by burnout of the insulation by the working voltage, due to a local increase in the moisture concentration during dehydration.

When the limit state is reached, there is an increased risk of damage to the transformer due to the occurrence of winding closure, when there are short-circuit currents, lightning and switching surges, and under the working voltage. The problem of determining the lifetime characteristics of paper insulation of power transformers that have been used for a long time consists of two parts: determination of the probability of damage to the transformer due to degradation of the insulation and an estimate of the residual life.

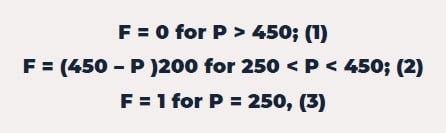

We must point out here the results of widescale investigations of 686 long-operating transformers in Japan. The probability characteristics of the damage to the transformers due to degradation of the insulation are defined by the following relations:

where P is the “present” value of the degree of polymerization and F is the probability of damage to the transformers due to insulation degradation.

The following equation was derived in [8] for the life of paper insulation of Japanese transformers, related to its degree of polymerization:

where P0 is the initial value of the degree of polymerization of the paper insulation of the transformer windings, and ô is the life of the transformer at the instant when the “current” value of the degree of polymerization was measured, in years.

It should, however, be noted that this relation mainly holds for foreign transformers. Russian power transformers are not equipped with a system of filters for continuously purifying the oil (thermosiphon or adsorption filters). The state of the outer layers of the insulation, covered with oil after prolonged use, as a rule, is worse than the state of the inner layers, in contact with the copper conductors. The latter is responsible for appreciable effects of oxidized and acidic products of the ageing of the paper insulation and the oil during insulation degradation.

When the power transformers are used with the regulated operation of the thermosiphon and adsorption filters, due to the constantly low concentration of catalysts of Reducing the Risk of Damage to Power Transformers of 110 kV and Above Accompanying Internal Short Circuits 485 the sludge formation and degradation, the value of the degree of polymerization of the outer layers of the winding insulation of the coils is higher than for the internal layers, in direct contact with the copper.

For transformers that have been used for a long time together with filters for directly purifying the transformer oil, one can assume that the method of estimating the residual life of the insulation, based on the actual kinetic behavior of the change in the degree of polymerization for different groups of power transformers with approximately the same load, is completely justified.

In this case, from the results of investigations the relation between the inverse degree of polymerization and the life take the form of a family of semilogarithmic anamorphisms:

where Keff is the effective rate constant of the destruction of the insulation during use, year–1.

From equation for P0 equal to the “current” value of the polymerization exponent, and P equal to 250, corresponding to complete exhaustion of the life of the insulation, we can determine the residual life of the insulation of transformers ôr.

where Keff is the effective rate constant of the destruction of the insulation during use, year–1. From equation (5) for P0 equal to the “current” value of the polymerization exponent, and P equal to 250, corresponding to complete exhaustion of the life of the insulation, we can determine the residual life of the insulation of transformers.

At present, on the basis of research which we have carried out, a fairly large database has been acquired for making practical kinetic estimates for determining the residual life of the insulation of power transformers that have been used for a long time based on the degree of polymerization.

The maximum values of the effective “annual” rate constant of the degradation of the paper insulation of the windings Keff for groups of power transformers with a different load are given below.![]()

These kinetic features enable us to formulate the following conclusions:

- The life of paper insulation of windings, of different groups of power transformer equipment, used in Russia, is determined by the annual rate constant of insulation degradation, which, as a whole, is a function of the load of the specific group of transformers, and the degree of polymerization of the initial wound paper, used for the winding insulation when it is manufactured;

- The degradation rate constant of the paper insulation of the windings of 220 – 500 kV network transformers is approximately half that for the 110 – 500 kV modular transformers of thermal power plants.

When there are dangerous deformations or a shift in the windings, the transformer may be damaged due to disturbance of the insulation and insulation gaps. When such a transformer is being used it is possible for partial discharges to occur, in which mainly hydrogen is formed.

It should be noted that, in publications of the SIGRE in 2008 examples are given of the damage of 16 shunting reactors due to the development of winding closures as a result of contamination of the insulation of the windings by metal-containing colloidal particles of copper sulfide CuS2 (5 – 7% by mass) when using oils containing sulfur, namely, Nitro 10 GBA and Nitro 10 GBN.

Methods being used at present to estimate the contamination of winding insulation, based on the measurement of the loss tangent of the dielectric insulation of the windings, only enable contamination of the winding insulation with respect to ground and between the windings to be determined.

The winding insulation is not monitored by this method. Winding closures remain of low sensitivity for a relatively long time for transformer protection devices (differential and gaseous) so long as the damage is isolated, as a rule, before an internal short circuit occurs.

Filters for continuously cleaning the oil (thermosiphon or adsorption filters) play an important role in reducing the risk of winding closures occurring. Thus for a mass of oil in the transformer of 50 tons, up to 230 kg or more of polar compounds — products of the ageing of the oil — may be adsorbed on the silica gel filters for continuously cleaning the oil.

It should be noted that the indicators of the concentrations of metal compounds of structural materials that are most dangerous in practice in winding insulation when there are filters for the continuous cleansing of the oil in the modern replacement of silica gel, as a rule, does not exceed 2% by mass.

For the purpose of increasing the operating efficiency of filters for continuously cleansing oil for the complete removal of both organic and mineral parts of the contamination of insulation materials, it is advisable to develop a new generation of sorbents by physical-chemical modification of the surface of the silica gels used at the present time.

In practice, RIP concentrator type insulation with hard polymer has been widely introduced. They provide the possibility of considerably reducing the risk involved when there are explosions and fires, and also dangerous actions on the environment.

However, at voltages of 220 – 500 kV, failure of these additives has been observed in a number of cases.

The insulation material of high-voltage leads operates under conditions of ionizing radiation of low-energy accelerated electrons in the presence of an electric field.

High-voltage leads with paper-oil insulation possess the property of “self restoration.” Here, plastification (filling) of the insulation paper with oil causes degeneration of the free radicals which are formed (particles with unpaired electrons) by their acceptance by the oil. This suppresses the development of the radiation destruction processes in the insulation paper which forms part of the paper-oil insulation when there are partial discharges.

Hence, oil is capable of absorbing and dissolving gaseous and other products of the decomposition of the oil and solid insulation, formed by the action of partial discharges which have a fairly strong deionizing action on the discharge channel.

For solid RIP-insulation, the damage arising from partial discharges accumulates. The main stages of the initial forms of disintegration, are as follows:

- Breaking of the bonds

- The formation of free radicals and their conversion into stable chemical groups

- The accumulation of molecular disintegrations followed by the production of submicrocracks.

Obviously, the formation of free radicals in the insulation may lead to a considerable local increase in the electrical conductivity in the region where there are partial discharges and their further development.

The rate of microprocesses then depends not on the average stresses but on the local stresses, which act in small regions, where elementary breaking of the bonds occurs.

When the level of partial discharges increases, the power of the absorbed dose of ionizing radiation increases, leading to a development of radiational erosion processes and, in the final analysis, rupture of the main lead insulation.

The use of RIP-insulation does not lead to damage of the high-voltage leads at voltages of 35 and 110 kV. Acquired experience in the use of leads at 35 and 110kV shows a fairly high level of reliability.

Nevertheless, damage to leads at 220kV and above indicates a fairly strict relationship between the structuralchemical and mass-size characteristics of RIP-insulation and its stability to operational effects, including intensive partial discharges. As follows from operating experience, highvoltage leads with RIP-insulation are prone to damage on parts with increased field strength — in the region of the mounting flange.

Recently, both in Russia and abroad, systems for the continuous monitoring the state of a transformer have become widely used. It is best to use the systems for the timely disconnection of a transformer before an arc, explosions or fires occur. On the basis of existing experience for these purposes, it is advisable to monitor the following factors continuously:

- The content of gases dissolved in the oil, primarily hydrogen,

- The moisture content of the oil;

- Partial discharges

This can be shown most clearly using the example of the damage to the TTs-400000500-UKhL1 type transformer, which was introduced into use in 2012. Regular relay protection was supplied to the transformer, as well as anti-accident automation and an automatic water fire extinguishing system.

Moreover, in addition to these, a system for the continuous observation of the content of combustible gases and the level of moisture in the oil was included, as well as a system for monitoring the characteristics of partial discharges, placed on the highvoltage leads of the transformer, together with a system for preventing explosions and fires in the transformer, manufactured by the Sergi Transformer Protector Company (the type MRT).

Fig. 1. Disruptive disk of the system for preventing explosions and fires in a transformer, manufactured by Sergi Transformer Protector Company after operation.

Emergency disconnection of the unit was caused by the action of the differential protection of the transformer. The operation of this and of the explosive disk brought about the operation of the system for providing protection from explosions and fires (the Transformer Protector system) and the fire protection system of the transformer. Triggering of the differential transformer protection occurred 22 msec after the occurrence of a short circuit, and the operation of the transformer disk occurred after 23 msec (the appearance of the disk after operation is shown in Fig. 1).

After 24 msec, a signal was generated to disconnect the circuit breakers, and to trigger the system for protection against explosions and fires (the Transformer Protector). After 29 msec the second stage of the gaseous protection of the transformer operated, and 48 msec later — stage I. Then, 52 msec later, the circuit breakers were disconnected. After 94 msec a signal “Operation of the preprotection valve” and “Overheating of the winding” (above 115°C) was generated. Regular relay protection and antiemergency automation have operated without observations.

The positive result of the operation of the Transformer Protector without a release of pressure and subsequent supply of nitrogen into the transformer tank has been pointed out. The absence of ignition and deformation of the transformer tank has been recorded.

Arc flashover of the upper half of the highvoltage phase B, having an input at the middle of the coil, was the reason for damage to the transformer. Arc flashover

occurred due to a reduction in the electric strength of the oil-barrier insulation, which caused the development of a creeping discharge over the surface of the electrically insulated cylinder, close to the transformer winding (Fig. 2).

Fig. 2. Creeping discharge tracks on the surface of an electrically insulated cylinder

As follows from the graph of the partial discharge pulses (Fig. 3), the maximum amplitude for breakdown of the first oil channel was noted 36 hours after the instant when the electric arc occurred. On the graph showing the content of inflammable gases and the level of moisture content of the oil of the HYDRAN M2 system (Fig. 4) one can see an increase in the level of the gas concentration after 36 h from the instant when an intense electric arc occurred from 22 to 70 ppm. The degree of

danger of the development of a defect is established from the relative rate of increase in the concentration of hot gases (Regulating Document RD 1530340-46.32–00, Izd. VNIIÉ, Moscow, 2000). This rate was 4363% in a month.

According to the Regulating Document RD 153-340-46.32–00, if the relative rate of increase of the gas/gases concentration (in this case the main gas is hydrogen) exceeds 10% per month, this indicates the presence of a rapidly developing defect in the transformer. The volume fraction of the hydrogen dissolved in the oil then amounted to 0.007%, i.e., it did not reach the limit value of 0.01% for the mass of oil of 47.39 tons after 36 h. An indicator of the relative rate of increase of gas, primarily hydrogen, which is the main indicator signaling a degree of danger of the development of a defect, is not provided in the HYDRAN M2 monitoring system.

For the operating settings for the operation of the warning and emergency signaling, specified by the factory-manufacturer of the HYDRAN M2 system, the signaling indicating breakdown of the equipment prior to the occurrence of an intense electric arc did not operate, since the values of the measured indicators did not reach the set level. To determine the degree of danger of the development of a defect, based on present experience, the operating setting indicating the level of hot gases should be set at a relative rate of increase in hydrogen and should not be less than 1000% per month.

At present, in the Russian standards, only the maximum value of the apparent charge qmax is used as the normalized characteristic of partial discharges, without indicating their intensity, which leads to a subjective estimate of the degree of danger of the partial discharges. Rupture of the insulation by single partial discharges occurs considerably more slowly than the rupture of the insulation by repeatedly formed partial discharges for the same value of the apparent charge.

In the IEC standard [22], it is established that, to estimate the degree of danger of insulation breakdown due to the action of partial discharges, one should use the maximum values of the apparent charge qmax of repeatedly forming partial discharges over one recording cycle.

Based on experience in diagnosing the insulation of 220 – 500 kV voltage transformers and an analysis of the acquired experimental data on the rupture of paper-oil insulation due to partial discharges, it is preferable to establish the criterion for repeatedly occurring partial discharges as being equal to 0.5, a danger level of an apparent charge due to partial discharges of not less than 10 nC, and a duration of one recording cycle of from 1 sec to 1 min.

It should be noted that when using electrical equipment, outside of the standard parameters, there is an increased probability of outages and, as a consequence, increased danger both for the equipment and for the lives and health of personnel.

The purpose of repair-preventive measures is to ensure that the transformer operates within its standard parameters, i.e., an object is transferred into the correct state in which it corresponds to all the requirements of the standard-technical and/or constructor (design) documentation.

All the indicators presented in the Regulating Document RD 34.45-51.300–97, with the exception of the degree of polymerization, the short-circuit resistance and the contamination by metal-containing colloidal particles, which are the main indicators of the limit state of the transformer, can be transferred to a state corresponding to the requirements of the above document, using repair-preventive measures or by replacing individual components of the transformer (high-voltage leads, oil, etc.).

In accordance with the requirement in Section 1.5 of the “Rule for the technical use of electrical plants and networks of the Russian Federation” (SPO ORGRÉS, Moscow, 2003), a technical inspection of electrical equipment is specified based on the standard technical documentation on the service life, and when carrying out each inspection, depending on the state of the equipment, the date on which the next inspection is to be carried out is noted.

The problems involved in technical inspection are estimating the state, and also determining measures necessary to ensure the established lifetime of the power equipment. Naturally this requirement also extends to the transformers.In this case, there is a need for commissions, which carry out technical inspections, in an established order in order to draw conclusions regarding the limit state of the transformer and, when the state of the transformer is approaching its limit state, to indicate the need (the desirability) to plan its replacement.

When a transformer reaches its limit state during use, before it is replaced one must make measurements of the moisture content and the breakdown voltage of the oil, and also carry out a chromatography analysis of the gases dissolved in the oil, primarily hydrogen, with a periodicity of once every six months in order reveal any reduction in the electric strength of the paper-oil insulation.

It is then advisable for the signal components of the gas relay to be transferred to the disconnection position, and to choose the order in which the circuit breaker is connected for the automatic repeat disconnection of the power lines from the end of the opposite substation, in which the transformer is established, or even to introduce a stop on the automatic repeat connection.

CONCLUSIONS

1

Systematic approaches have been developed and sufficient experience has been acquired, which now enable the principles of the complex approach to estimating the technical state of power transformers to be stated, and enable the limit state to be determined and decisions taken for the purpose of reducing the risk of damage, explosions and fires in transformers. Nevertheless, there is a need to continue the investigations and to draw up, on the basis of these, a number of important documents designed to obtain more complete and reliable information to estimate the operating capability of transformers.

In particular, the following requirements need to be stated:

- the need to develop “procedures for estimating the limit state when carrying out a technical inspection of transformers”;

- the need to develop a standard on “criteria for estimating the contamination of the winding insulation of transformers, autotransformers and miniature reactors by metal-containing colloidal particles”;

- the need to investigate a new generation of sorption materials in filters for the continuous cleansing of the oil for the complete removal of both organic and mineral parts of contaminations in order to prolong the life of transformers.

2

A fairly complete methodology has been developed at the present time for estimating the residual life of the paper insulation of transformer windings, which should be calculated using the parameter of the degree of polymerization based on its actual variation dynamics.

3

The most urgent problem is to use a system of monitoring to indicate the processes that occur when internal short circuits develop in a transformer at the stage when electrical damage is developing, preceding the occurrence of an electric arc. To achieve this, one must specify monitoring of the gas content, primarily hydrogen, the moisture content in the transformer oil and the partial discharges. It is necessary to develop a standard basis for taking a decision on withdrawing a transformer from operation before an electric arc occurs by using a monitoring system.