ABSTRACT:

Waste-to-energy technology plays a pivotal role in advancing the circular economy by transforming waste into valuable energy resources. However, as this industry grows, the risks associated with transformer explosions and fires pose significant challenges to both energy production and environmental safety.

Electrical transformers, critical components of energy generation plants, are vulnerable to failures that can disrupt operations and damage the environment. SERGI’s TRANSFORMER PROTECTOR (TP) offers a proven solution to prevent such disasters, safeguarding transformers from explosions and fires caused by low impedance failures. By integrating the TRANSFORMER PROTECTOR into waste-to-energy facilities, companies can secure their assets, maintain financial stability, and contribute to environmental protection by preventing harmful leaks and fires.

Waste-to-Energy Technology and the Vital Role of Electrical Transformer Protection

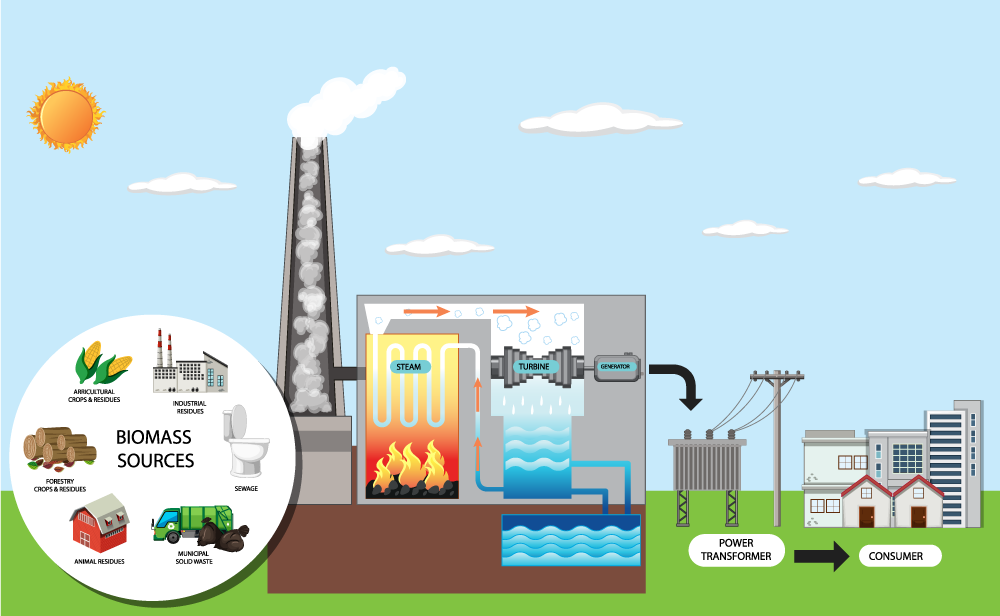

Waste-to-energy (WtE) technology has become a key component in transitioning toward a circular economy, providing an innovative solution to both energy generation and waste management. By converting waste materials into energy, WtE facilities reduce reliance on finite resources and decrease environmental impact. This aligns perfectly with the principles of the circular economy—reuse, resource efficiency, and minimizing waste. As cities and industries grow, WtE technology is increasingly recognized as a sustainable solution to the world’s growing energy demands.

At the heart of the circular economy is the need to rethink our approach to resource management, extending product lifecycles and maximizing efficiency. Waste-to-energy plants embody these goals by turning non-recyclable waste into electricity, heat, or biofuels. According to the U.S. Department of Energy, “waste streams have untapped potential to produce high-impact renewable energy”1. Similarly, the U.S. Environmental Protection Agency (EPA) highlights that modern WtE plants can reduce waste volumes by up to 90% while generating significant amounts of electricity. However, while WtE facilities offer immense benefits, their electrical infrastructure, particularly transformers, faces increased risks as these plants scale up operations.

Transformers play a crucial role in WtE facilities, enabling the conversion of waste-derived energy into usable electricity for the grid. However, low impedance failures—caused by short circuits or other electrical faults—can lead to a rapid rise in internal pressure within transformers. If not managed, this pressure can result in catastrophic explosions and fires, threatening the safety of the plant, its personnel, and the environment. The financial consequences are also significant, with transformer failures leading to costly downtime, repairs, and potential regulatory fines.

This is where SERGI’s TRANSFORMER PROTECTOR (TP) becomes indispensable. The TP is an advanced safety system designed to detect internal pressure buildup in real-time, reacting within milliseconds to prevent explosions and fires. By quickly isolating the transformer and venting the excess pressure, the TP ensures operational continuity, protecting both the plant and its workers. This proactive solution is particularly crucial in waste-to-energy plants, where transformer failures can halt energy production and lead to massive financial losses.

Moreover, the role of the TP extends beyond immediate safety concerns. Transformer explosions can release toxic materials and oil, leading to soil, groundwater, and ecosystem contamination. Fires caused by transformer explosions require extensive firefighting efforts, which can further pollute nearby water bodies with foam and chemicals. By preventing such incidents, the TP supports the environmental goals of WtE plants, ensuring they remain aligned with the sustainability objectives of the circular economy.

Financial Stability and Environmental Responsibility

The protection of transformers is not just about preventing fires—it is about ensuring the long-term financial and environmental stability of WtE facilities. As transformers are high-value assets, their failure can result in extensive downtime and costly replacements, threatening the financial viability of the plant. By integrating the TP, WtE plants can maintain continuous energy production and protect their investment, securing both profitability and operational efficiency.

From an environmental perspective, preventing transformer explosions reduces the risk of oil spills, fires, and hazardous material release. This makes the TP an essential component in maintaining the sustainability of WtE plants. Companies utilizing the TP solution can confidently generate clean energy while minimizing their environmental footprint, reinforcing their commitment to the circular economy and resource efficiency.

Conclusion:

IN CONCLUSION, WASTE-TO-ENERGY TECHNOLOGY, COMBINED WITH SERGI’S TRANSFORMER PROTECTOR, OFFERS A COMPREHENSIVE SOLUTION TO THE DUAL CHALLENGES OF SUSTAINABLE ENERGY GENERATION AND ENVIRONMENTAL PROTECTION. BY SAFEGUARDING TRANSFORMERS FROM FAILURES, THE TRANSFORMER PROTECTOR ENSURES OPERATIONAL SAFETY, FINANCIAL RESILIENCE, AND ENVIRONMENTAL STEWARDSHIP, ALLOWING WASTE-TO-ENERGY PLANTS TO CONTINUE CONTRIBUTING TO A CLEANER, MORE SUSTAINABLE FUTURE.